Electrokinetic In Situ Recovery (EK-ISR)

Electrokinetic in situ leaching (EK-ISR) is a novel mining technology aimed at recovering copper and other metals from orebodies without physical excavation, thereby significantly reducing the environmental footprint of mining operations.

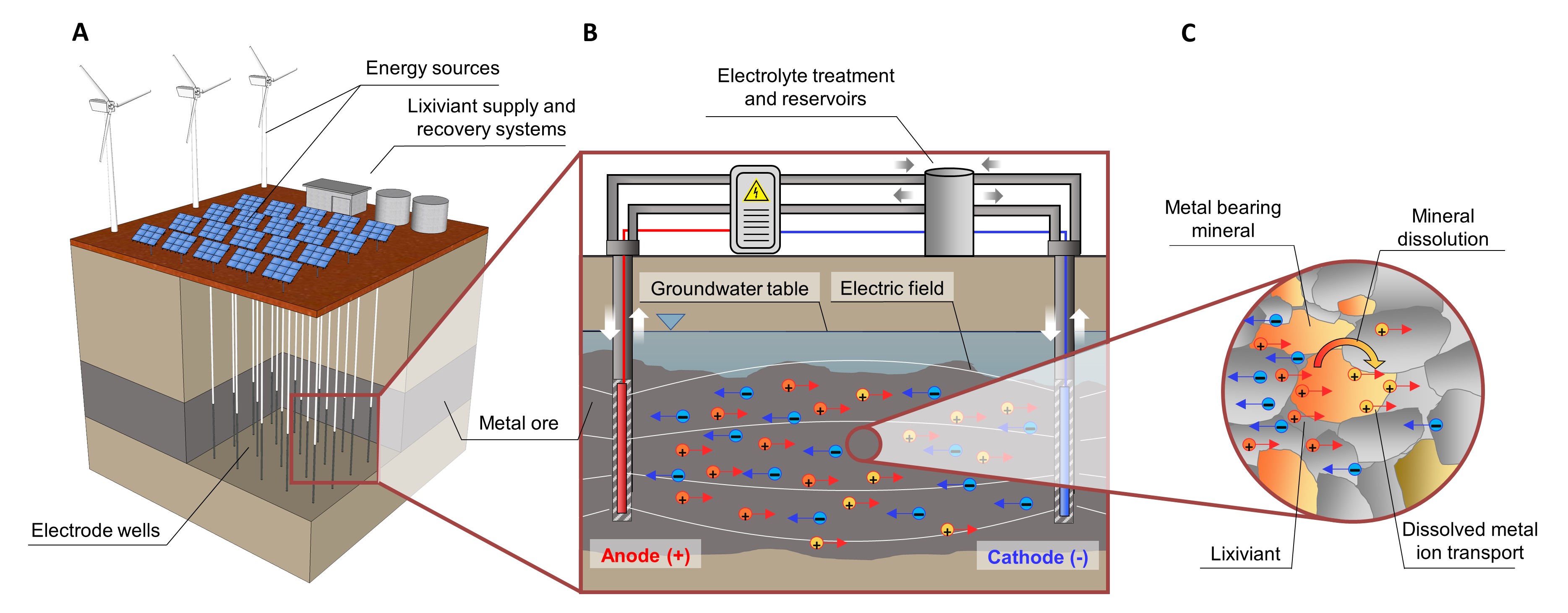

EK-ISR combines two existing technologies: (i) in situ leaching (ISR), which comprises the application of a lixiviant to selectively dissolve target metal(s) from their ore without removal of its host matrix, i.e., without excavation, and (ii) electrokinetics (EK), which comprises the application of a targeted electric field to control and accelerate transport (via electromigration) of lixiviants and/or dissolved target metal(s) within the subsurface.

Figure 1. From Martens et al. 2021.

EK as such is a relatively mature technology that has previously been applied in several fields of engineering, including metal recovery from fly ash (Ferreira et al., 2005), wastewater sludge (Jakobsen et al., 2004), soils, and mine tailings materials (Ortiz-Soto et al., 2019).

Its application to recover metals from intact hard rock bodies (e.g., primary ore deposits), however, is novel. Here, electrodes of opposite polarity are placed either within, or surrounding the ore, with cation migration directed toward the cathode(s) and anion migration toward the anode(s).

The lixiviant is introduced via an external source reservoir and leached metals are collected from a target reservoir, which contains electrode(s) exhibiting opposite charge to the target metal-bearing ion. This setup (Figure 1) allows for a precise control over the transport of both the lixiviant and the dissolved target metal(s) within the ore body.

As solute transport occurs via electromigration, this enables a relatively rapid movement of ions through low hydraulic conductivity media, thus circumventing the need for permeability enhancement techniques, such as hydraulic fracturing. The dependence of the transport on electromigration promotes a uniform delivery of the lixiviant to the target metal(s) that are not limited to specific preferential flow paths that might host only a small fraction of the total grade.

This is a transformative benefit given the tight (typical hydraulic conductivity < 10e−7 m/s) and heterogeneous nature of most ore deposits, including Cu ore deposits.

To date, the EK-ISR process has been studied through (i) cm-scale laboratory experiments and (ii) process-based numerical modelling to assess the feasibility and scalability of EK-ISR for Cu extraction.

Martens et al. (2021) provided an initial proof-of-concept for the viability of EK-ISR across an intact sample consisting of sulfidic porphyry ore material and to recover a significant fraction of the ore-hosted Cu. Based on this work, Ortega-Tong et al. (2023a) investigated the EK-induced Cu leaching process further, with a specific focus on a detailed characterisation of the secondary leaching products that form at the surface of the Cu-sulphides and whether the EK-induced conditions would eliminate or decrease the often-observed passivation of Cu-sulphides, thereby slowing down or completely arresting the Cu leaching process.

These experiments showed successful Cu recovery from a variety of ore types and recovery rates of up to 100% for selected samples. Demonstrating the viability and efficiency of EK-ISR at the field-scale is a key step in the further development of EK-ISR.

References

- Acar, Y.B., and Alshawabkeh, A.N. (1993). Principles of electrokinetic remediation. Environ. Sci. Technol. 27, 2638–2647.

- Ferreira, C., Jensen, P. , Ottosen, L., and Ribeiro, A. (2005). Removal of selected heavy metals from MSW fly ash by the electrodialytic process. Eng. Geol. 77, 339–347.

- Jakobsen, M.R., Fritt-Rasmussen, J., Nielsen, S., and Ottosen, L.M. (2004). Electrodialytic removal of cadmium from wastewater sludge. J. Hazard. Mater. 106, 127–132.

- Kuhar LL, Chapman N, Paton S, Walton G, Meakin R, McDonald R, Li J, Evans A, and Davies M (2021) Phases 3 and 4: Mini-column and large-particle saturated column leach tests. CSIRO, Australia.

- Martens, E., Prommer, H., Sprocati, R., Sun, J., Dai, X., Crane, R., Jamieson, J., Tong, P.O., Rolle, M., and Fourie, A. (2021). Toward a more sustainable mining future with electrokinetic in situ leaching. Science Advances, 7(18).

- Newton, A. W. Mineral Exploration and Development in South Australia, 1st ed.; Mines and Energy South Australia: Eastwood, Australia, 1996.

- Ortega-Tong, P., Jamieson, J., Bostick, B. C., Fourie, A., and Prommer, H. (2023a). Secondary phase formation during electrokinetic in situ leaching of intact copper sulphide ore. Hydrometallurgy, 216, 105993.

- Ortega-Tong, P., Jamieson, J., Kuhar, L., Faulkner, L., and Prommer, H. (2023b). In-Situ Recovery of Copper: Identifying Mineralogical Controls Via Model-Based Analysis of Multi-Stage Column Leach Experiments. Env. Sci. Technol. Eng. (in press)

- Ortiz-Soto, R., Leal, D., Gutierrez, C., Aracena, A., Rojo, A., and Hansen, H. K. (2019). Electrokinetic remediation of manganese and zinc in copper mine tailings. J. Hazard. Mater. 365, 905–911.